Determine a range of appropriate methods for recognizing geometric shapes (square, circle, rectangle, etc.). In the first stage, objects placed in the normal position as to determine the geometrical shape feature. However the field of artificial vision is a common discipline both image processing and artificial intelligence. The image thus obtained is extracted useful information. This information is taken from the intelligent sensors, and creates an image of the environment when taking data. All these imply, however, accumulating a certain amount of information (knowledge base, environmental information, etc.). On the other hand, artificial intelligence requires intersection area and building systems capable of performing the functions of the human intellect: experiential learning, natural language understanding and the use of reasoning to solve problems or make decisions. A significant number of high-performance algorithms used in image processing using methods and techniques of artificial intelligence.

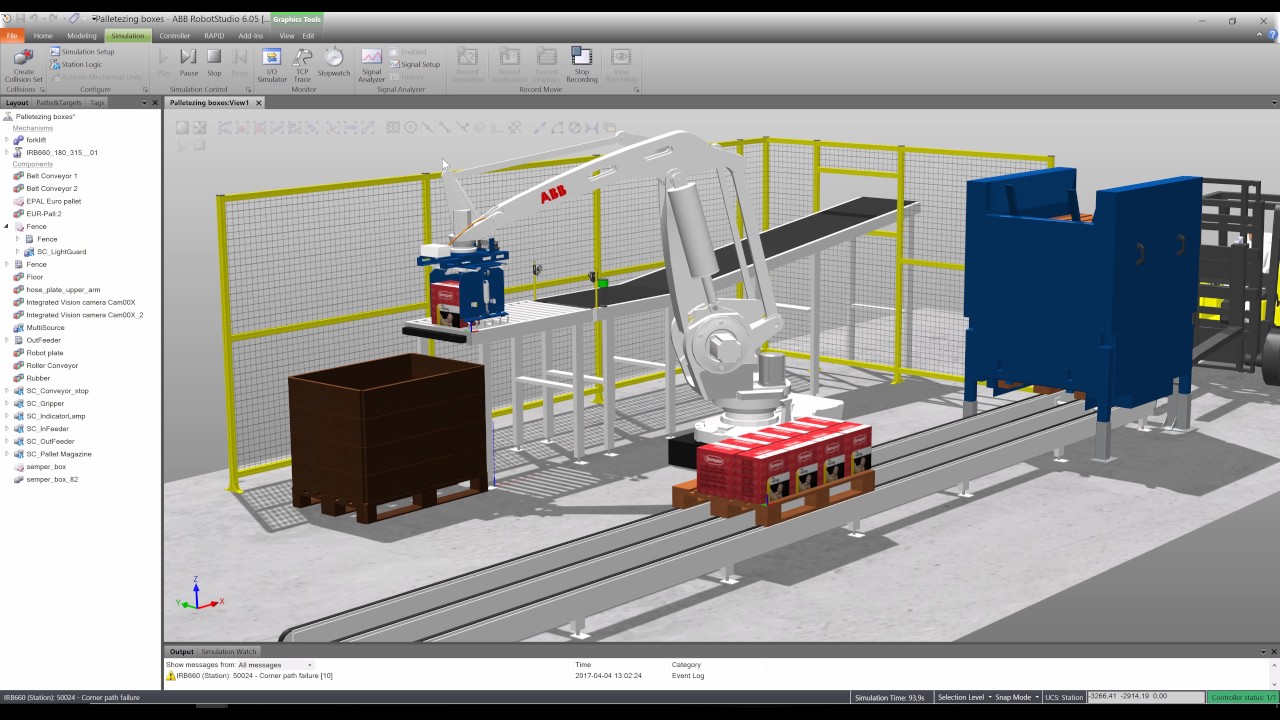

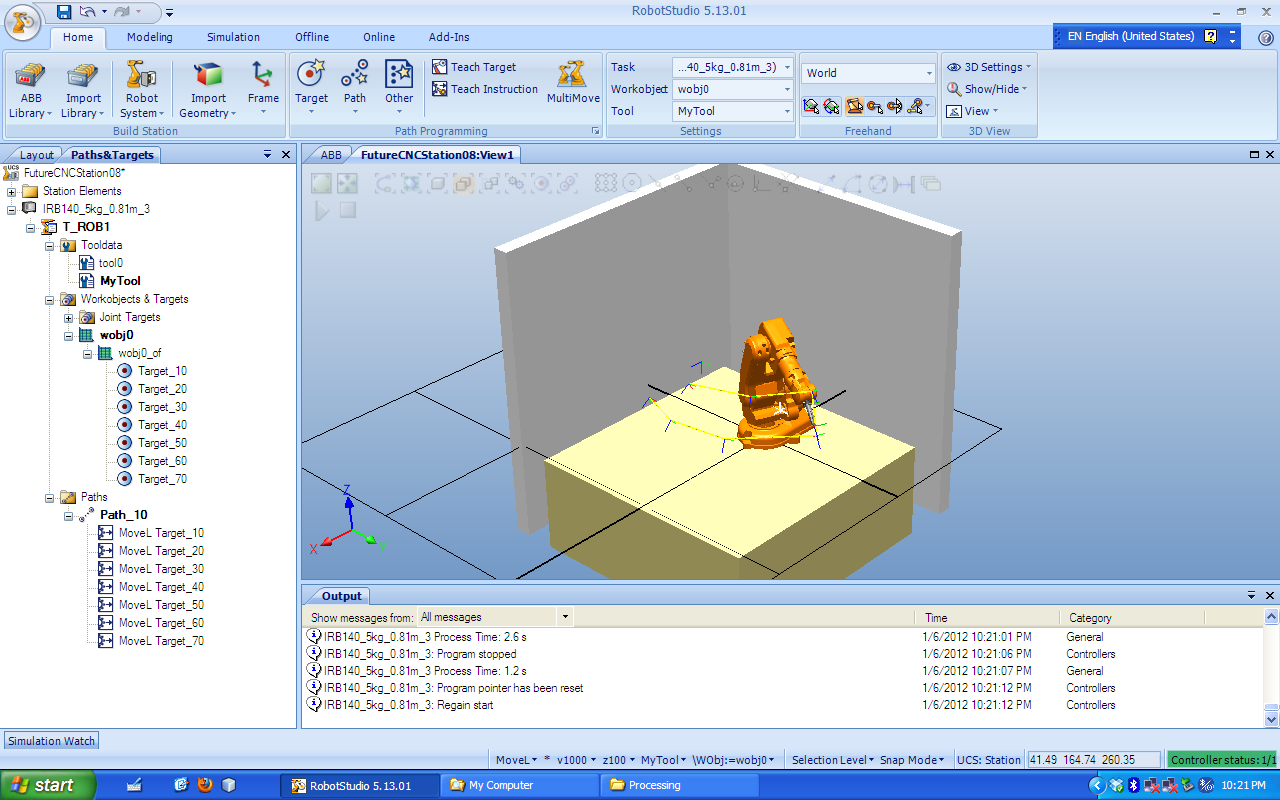

Using offline programming of robots ABB RobotStudio program is ordered using these objects in a predetermined order. Physics based dress pack simulations gives the user information if the dress pack is too long or too short or follows a trajectory that can cause damges.The paper presents finding certain geometric objects in an image of the work area. Physics adds accuracy to the offline programming model and also simplifies the modeling since animations are automatically handled by the physics.

With the inclusion of physics simulations, the automation engineer can now also model dynamics of the surrounding robot cell and the material that the robots works with.

This provides numerous benefits including: ABB’s simulation and offline programming software, RobotStudio, allows robot programming to be done on a PC in the office without shutting down production.ĪBB RobotStudio provides the tools to increase the profitability robot systems by letting the user perform tasks such as training, programming, and optimization without disturbing production. Offline programming is the best way to maximize return on investment for robot systems. ABB has selected AGX Dynamics from Algoryx to power simulations of multibody systems and hose dynamics. The latest release of ABB RobotStudio, the world’s most used offline programming tool for robotics, now comes with support for advanced realtime physics simulation. Michael Brandl, running the Algoryx office in Munich, Germany, at the Hannover fair when ABB RobotStudio with AGX Dynamics was announced.

0 kommentar(er)

0 kommentar(er)